In industries where bulk liquids must be stored and transported safely, efficiency and protection are critical. From food and beverages to chemicals and pharmaceuticals, businesses need solutions that maintain product integrity while streamlining operations. This is where IBC liners come in.

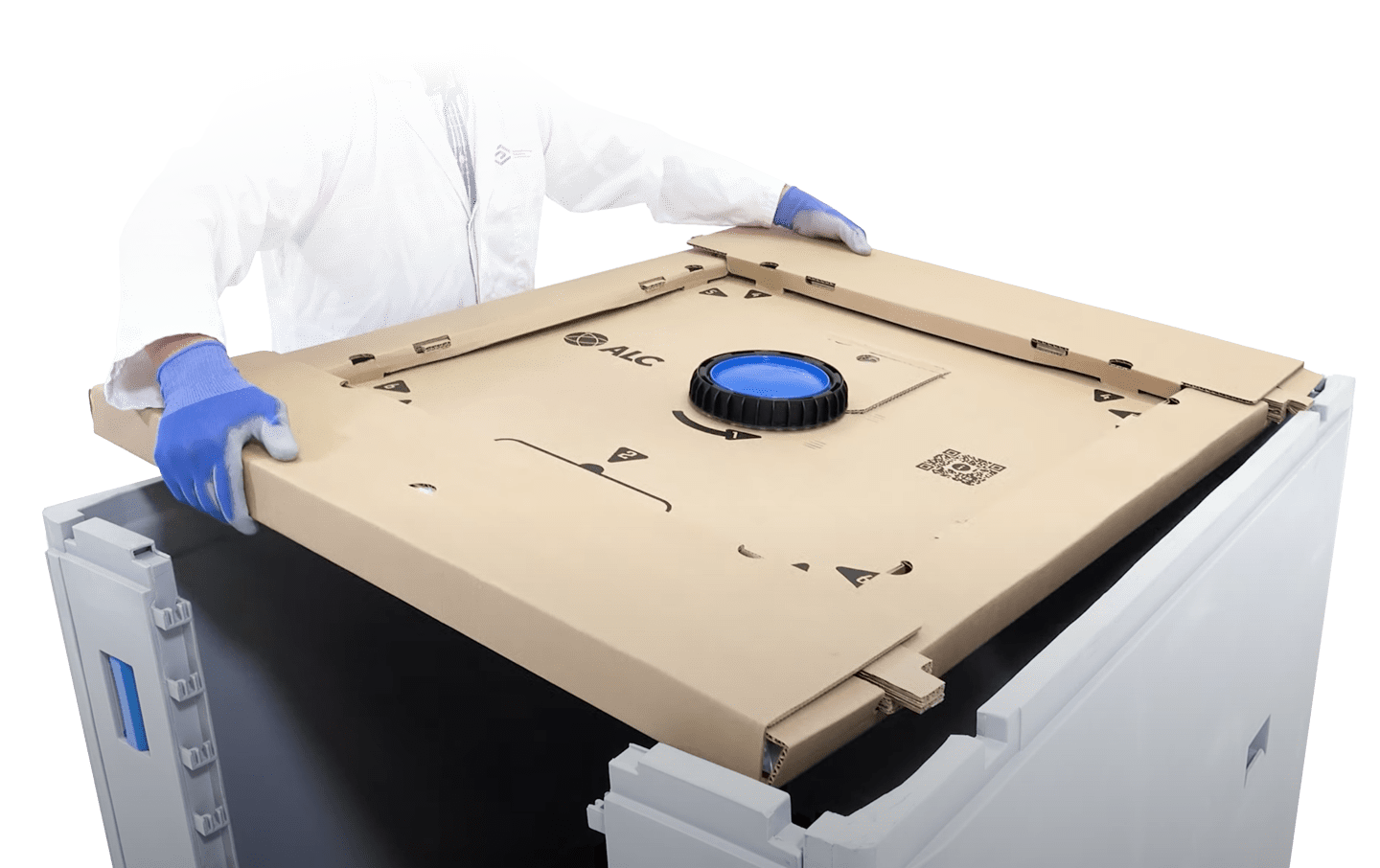

An IBC liner is a specially designed flexible film insert placed inside an intermediate bulk container (IBC). These liners create a hygienic barrier between the liquid and the container, allowing for safe, efficient, and contamination-free handling of a wide variety of liquids. Whether you’re shipping fruit concentrates, pharmaceutical ingredients, or industrial chemicals, an IBC liner bag can provide the security and flexibility your operation needs.

Understanding Bulk Liquid Packaging Solutions

When considering the safest and most cost-effective way to manage liquids in large volumes, companies often turn to bulk liquid packaging solutions like IBC liners. Traditional methods such as drums or stainless-steel tanks have their place, but they can involve high cleaning costs, limited reusability, and logistical inefficiencies.

By contrast, liquid tote liners streamline operations by:

- Minimizing cleaning requirements between uses.

- Allowing one container to handle multiple products without cross-contamination.

- Reducing downtime associated with product changeovers.

As a result, intermediate bulk container liners have become a trusted tool across industries seeking both safety and efficiency.

The Different Types of IBC Liners

Not all liners are created equal. Depending on the product, viscosity, and handling requirements, you may choose from several types:

- Pillow liners – Flexible and economical, these are ideal for low-viscosity liquids such as juices, oils, and syrups.

- Form-fit liners – Designed to match the exact shape of the container, these liners work best for viscous products like adhesives, resins, or creams, ensuring complete product discharge with minimal residue.

- Barrier liners – Built with multi-layer films, barrier liners prevent oxygen, moisture, and UV penetration, extending shelf life for sensitive products.

- Anti-static liners – Specialized for chemical and industrial use, these liners reduce static buildup and improve handling safety.

By choosing the right liner style, businesses can tailor their packaging solution to meet both product requirements and operational goals.

Benefits of Using IBC Tank Liners

The advantages of integrating IBC tank liners into your workflow go beyond convenience. They also include:

- Product Protection – Liners shield liquids from external contaminants, maintaining purity and quality.

- Cost Savings – Eliminating intensive cleaning reduces labor and water use.

- Operational Flexibility – One container can safely store multiple product types by simply switching liners.

- Environmental Considerations – By minimizing waste and reducing chemical cleaning agents, liners support greener business practices.

Industrial IBC Liners Across Applications

Because of their adaptability, industrial IBC liners are widely used across multiple industries:

- Food and Beverage – Fruit concentrates, dairy bases, syrups, and edible oils.

- Pharmaceuticals – Active ingredients, nutritional supplements, and sterile liquids.

- Chemicals – Solvents, detergents, acids, and resins requiring resistance and containment.

- Cosmetics and Personal Care – Lotions, gels, and other viscous formulations.

This versatility explains why many companies actively search for IBC tote liners for sale that meet their exact product specifications.

Choosing the Best Liner

With so many liner types available, it’s important to match the liner to your liquid’s unique needs. Product viscosity, temperature sensitivity, and regulatory compliance all play a role in the decision-making process.

To dive deeper into this topic, explore Choosing The Right IBC Liner For Your Liquid Packaging Needs. This resource breaks down the factors you should weigh to make the best choice for your operation.

Are IBC Liners Reusable?

While some heavy-duty liners may be reused under specific conditions, most are designed for single-use. This ensures product purity, eliminates the risk of cross-contamination, and simplifies operations by removing the need for cleaning. For industries with strict regulatory requirements, such as pharmaceuticals or food production, single-use liners are the standard.

So, what are IBC liners? They are a cornerstone of modern bulk liquid packaging solutions, offering a cost-effective, safe, and adaptable way to handle liquids across diverse industries. From liquid tote liners for food products to industrial IBC liners designed for chemicals, there’s a solution tailored for nearly every application.

If your business is ready to improve storage, transportation, and product safety, consider investing in a liquid bulk container liner system that fits your needs.

For those looking for an in-depth exploration of liner types, benefits, and applications, don’t miss The Ultimate Guide To IBC Liners And Bulk Liquid Packaging. It’s an excellent resource for businesses that want to optimize their packaging strategies while maintaining safety and efficiency.

Want expert advice on the right liner for your application?

Call 815-963-9525 today or contact Innovative Liner Solutions through our website. Our team is ready to help you find the perfect fit for your packaging needs.