Intermediate Bulk Containers (IBCs) are widely used for transporting and storing liquids because of their durability, efficiency, and cost-effectiveness. However, the true success of an IBC system lies in its protective components. Among these, IBC top lids play a crucial role in ensuring that the container remains sealed, secure, and contamination-free. Without proper top lids, even the strongest IBC packaging materials would fall short of providing complete protection. Understanding why these lids are important helps businesses make informed decisions about safeguarding their valuable products.

The Purpose of IBC Top Lids

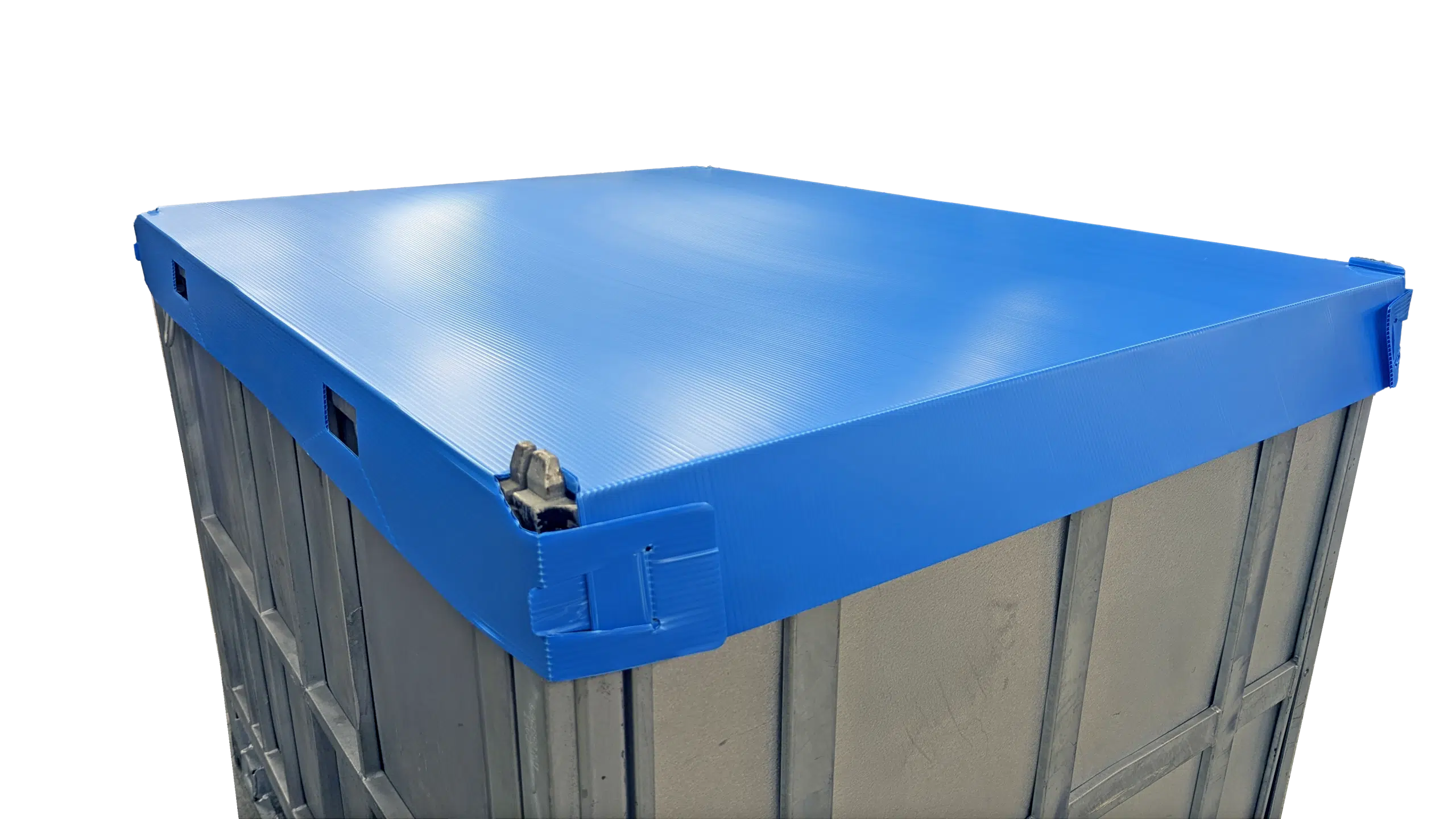

IBC top lids are designed to close off the container and maintain a barrier against external contaminants such as dust, debris, and moisture. They also secure protective container liners in place, preventing them from shifting during transport or storage. By sealing the container tightly, top lids minimize the risk of product exposure, which is critical for maintaining the quality and safety of liquids.

In industries where hygiene is paramount, such as food, beverages, and cosmetics, lids are particularly vital. For chemicals, top lids ensure safe handling by preventing leaks or accidental exposure. This makes them a standard requirement across all industries that rely on IBCs.

How Top Lids Work With Liners

Protective liners, including polypropylene container liner options, form the inner barrier that separates the liquid from the container walls. However, without a secure top lid, the liner may not stay in place or could be compromised during filling, transport, or dispensing. Top lids ensure that liners remain properly aligned, reducing the chance of shifting or tearing.

When used with open top liners, lids provide a final seal after installation, completing the protective system. This combination gives businesses confidence that their products are safe from contamination while also allowing for easier liner replacement when needed.

The Role of Dunnage Boards, Base Pads, And Top Lids In IBCs

Top lids are just one part of a complete protective packaging system. Dunnage boards distribute weight evenly across the container, reducing stress on the liner. Base pads cushion the bottom of the IBC, protecting against wear during handling and shipping. Together with top lids, these components create a balanced structure that reinforces both the container and its liner. To learn more about how these elements work together, review this resource on The Role Of Dunnage Boards, Base Pads, And Top Lids In IBCs.

Benefits of Using IBC Top Lids

The benefits of using IBC top lids extend beyond simple containment. They include:

-

Contamination prevention: Lids keep out airborne particles and other contaminants.

-

Product safety: They reduce the risk of spills and leaks during transport.

-

Structural support: By securing the liner, lids help maintain stability inside the container.

-

Improved efficiency: Lids simplify handling by ensuring that containers remain properly sealed throughout the logistics process.

These advantages make top lids a critical element in IBC protective packaging supplies, ensuring businesses meet safety and quality standards.

Applications Across Industries

Different industries depend on top lids for unique reasons. In food and beverage, lids preserve the purity of products like syrups, juices, and edible oils. In the chemical sector, lids prevent hazardous liquids from escaping and protect workers from exposure. Cosmetic companies rely on them to maintain cleanliness for lotions, gels, and creams. Even in automotive applications, lids keep lubricants and coolants securely contained.

No matter the industry, the function remains consistent: protecting the liquid product by providing a reliable closure system.

How Top Lids Improve Transport Safety

Transporting liquids requires containers to withstand movement, vibration, and potential impacts. Without secure lids, protective liners could shift, increasing the risk of leaks. Top lids prevent this by holding the liner in place and maintaining the seal at the container’s opening. This ensures liquids remain intact during long-distance shipping, whether by road, rail, or sea.

Top lids also reduce liability by minimizing the chance of spills that could damage surrounding cargo or create safety hazards during transport.

Supporting Bulk Liquid Packaging Components

Top lids are most effective when used in combination with other bulk liquid packaging components. IBC dunnage boards, base pads, open top liners, and container lids all work together to reinforce the container system. This integrated approach ensures that every part of the IBC is supported, protected, and prepared for the challenges of storage and distribution.

Each component plays a distinct role, but together they create a complete protective solution that enhances the reliability of bulk liquid packaging.

Sustainability Considerations

In addition to safety and efficiency, top lids contribute to sustainability goals. By protecting liners and reducing the risk of damage, they extend the life of IBC containers. This minimizes waste by reducing the number of liners or containers that must be discarded due to failure. Lids also support more efficient reuse cycles, cutting down on the need for energy- and resource-intensive cleaning processes.

Choosing the Right Packaging System

Selecting the best top lids requires evaluating the type of liquid being shipped, regulatory requirements, and operational needs. Some applications may require stronger sealing mechanisms, while others may prioritize ease of liner replacement. Businesses seeking detailed guidance on selecting the right components can review the Comprehensive Guide To IBC Packaging Materials And Components.

Why Partner with Innovative Liner Solutions

Innovative Liner Solutions offers a complete range of IBC packaging materials, including top lids, container lids, dunnage boards, base pads, and liners. Their expertise ensures that businesses across industries can implement safe, efficient, and sustainable packaging solutions. By working with a provider that understands the technical and operational demands of bulk liquid shipping, companies gain reliable protection for their products and peace of mind.

Conclusion

IBC top lids are an essential part of bulk liquid packaging systems. They protect liquids from contamination, stabilize liners, and ensure containers remain sealed throughout shipping and storage. When used with dunnage boards, base pads, and other protective components, they create a reliable system that maintains product safety and efficiency across industries. For any business that depends on bulk liquid shipping, investing in high-quality top lids is a step toward reducing risk and improving operations.

For expert advice on IBC top lids and protective packaging systems, contact Innovative Liner Solutions today at (815) 963-9525.