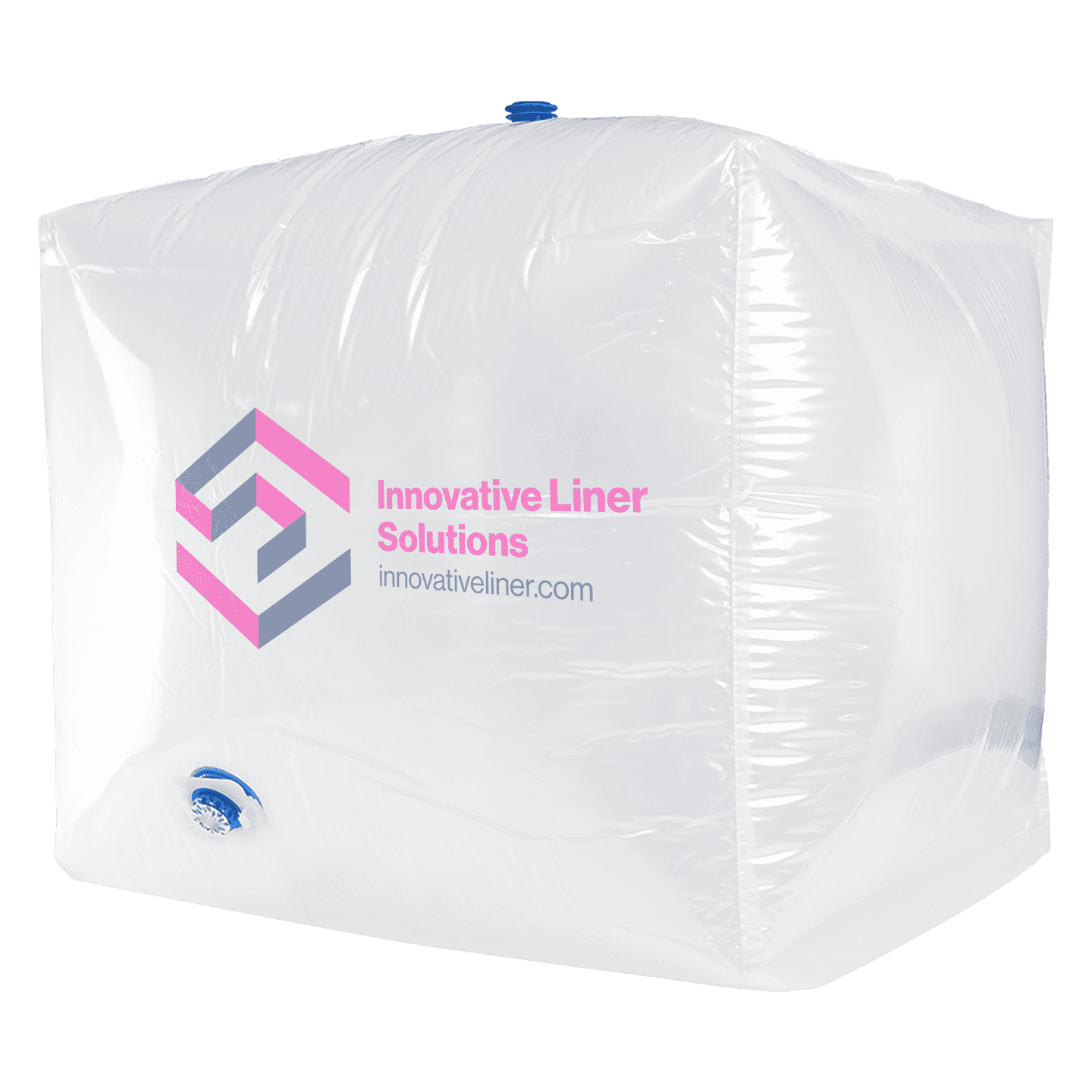

IBC Liquid Liners

Optimize Your Liquid Handling with High-Quality IBC Liners

Innovative Liner Solutions provides a wide range of IBC liners designed to ensure safe, efficient, and cost-effective storage and transport of liquid products. Our liquid bulk container liners are manufactured in an ISO Class 7 cleanroom, guaranteeing the highest level of quality and cleanliness. Whether your business requires aseptic, high-viscosity, or standard liquid containment, our industrial liquid containers and liners offer superior protection and performance.

Advanced Liner Materials for Optimal Protection

Liquid liners are available in quad form fit, pillow style, with and without O2 barrier films, aseptic/non-aseptic, and various fill and drain valves. Our IBC liners are available in a variety of high-performance materials, including:

Aseptic and Non-Aseptic Films

Multi-layer Nylon and EVOH Co-Extrusions

Metallized Polyester Laminations

Polyethylene Liquid Containment Options

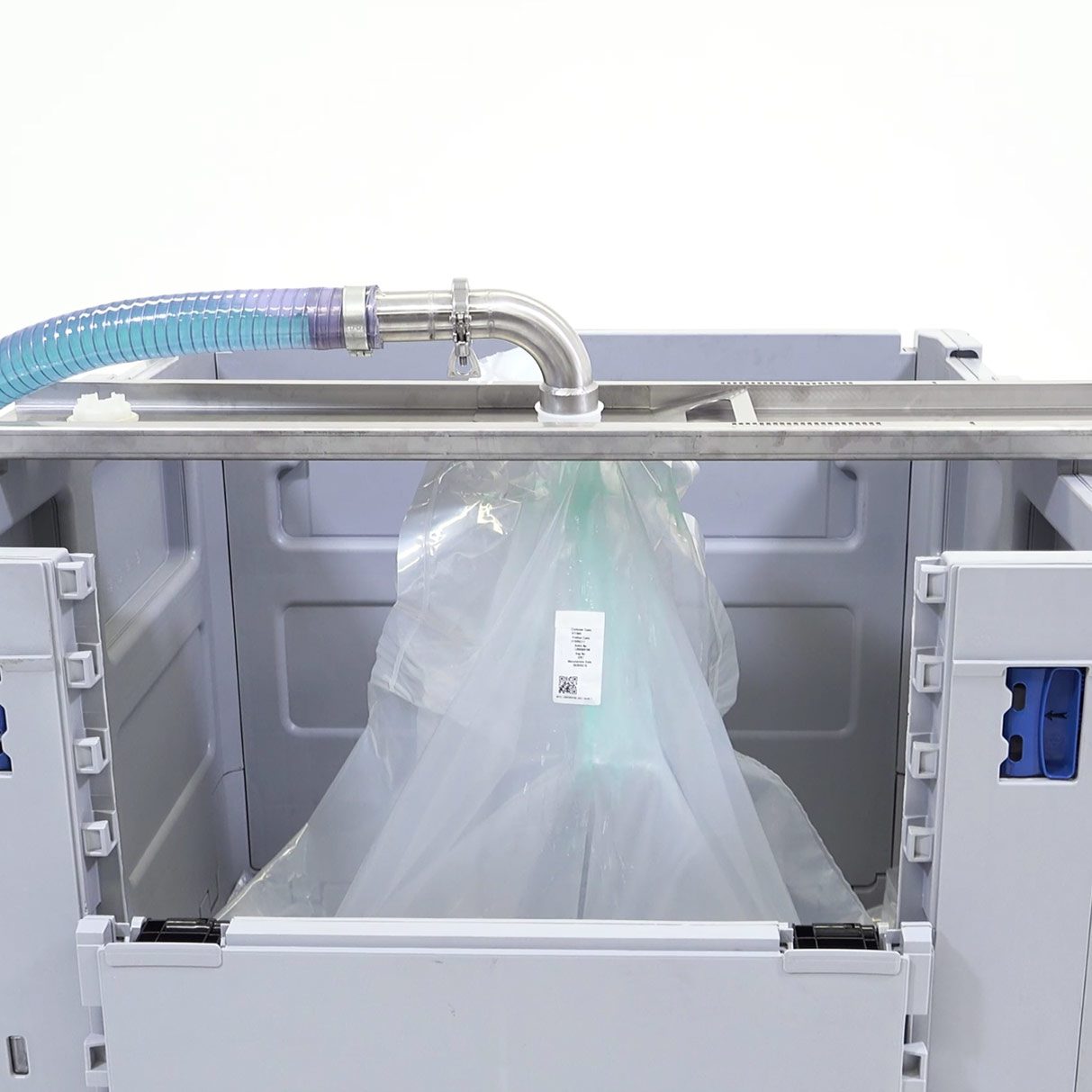

Types of IBC Liners

At Innovative Liner Solutions, we provide multiple liner configurations to suit various needs.

Classic Quad

Airmax/ Airmax+

Auto Quad

Pillow Liner

Optimize Your Bulk Storage & Transport with Innovative Liner Solutions

We provide cutting-edge bulk packaging solutions tailored to your business needs. Explore our products to learn more about how we can improve your operations.

Find the Right IBC Solutions for Your Business

Optimize your liquid handling operations with our high-quality IBC liners, containers, valves, connectors, discharge tubes, and more. No matter your industry—food processing, chemicals, pharmaceuticals, or manufacturing—we have the solutions you need. Contact us today for pricing and expert guidance!