Intermediate Bulk Containers (IBCs) are one of the most efficient and widely used solutions for bulk liquid shipping.

Their rigid outer shells and stackable frames make them ideal for handling, storing, and transporting large quantities of liquid across industries. However, the IBC container itself is only part of the system. To ensure safety, cleanliness, and long-term performance, additional IBC packaging materials are needed to protect both the container and the valuable products inside.

Among the most important of these are IBC dunnage boards, IBC base pads, and IBC top lids. Together, they reinforce the container from all angles, helping protective container liner systems function effectively while reducing the risks of leaks, contamination, and structural damage. This page explains in detail the role of these packaging components, why they are essential, and how they work with liners and other IBC protective packaging supplies to create a reliable system for bulk liquid logistics.

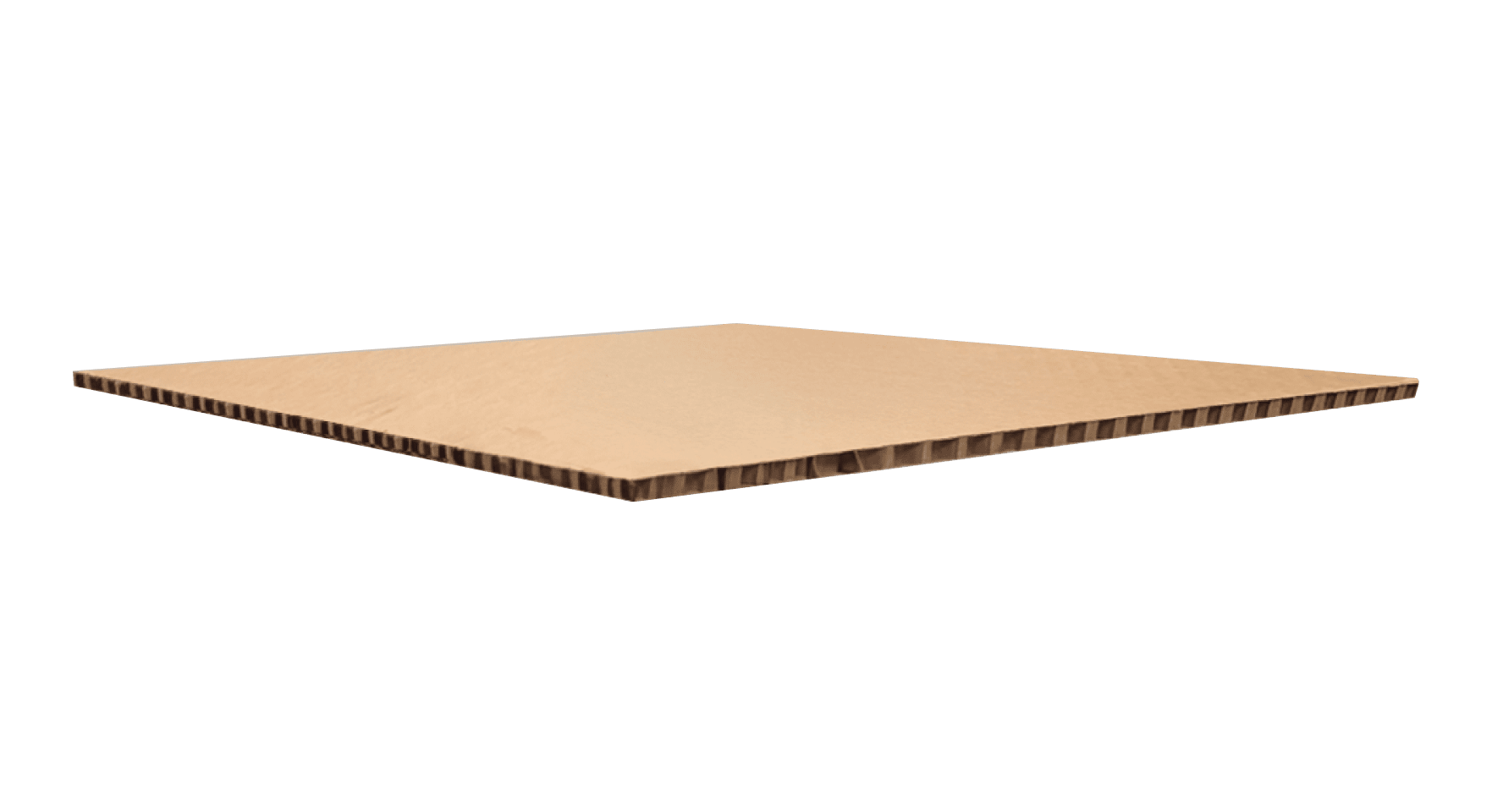

What Do Dunnage Boards Do In An IBC Container?

IBC dunnage boards are a vital part of the protective system that keeps bulk liquid shipments secure.

These components are designed to provide internal reinforcement by distributing the weight of liquid evenly throughout the container. Without this support, pressure can concentrate in certain areas of the protective container liner, increasing the risk of stretching, punctures, or liner failure. By spreading out the force of the liquid, dunnage boards act as a stabilizing layer that safeguards both the liner and the container, helping maintain product integrity throughout handling, storage, and shipping.

Why Weight Distribution Matters

Liquids naturally exert hydrostatic pressure in every direction, and the larger the volume of liquid, the greater the force on container walls and liners. In a filled IBC, this pressure is not always evenly balanced, particularly during transit when containers are subject to movement, vibration, or stacking. These constant shifts can create concentrated stress points inside the container. If unmanaged, the result can be weak spots in liners that eventually tear or fail.

Dunnage boards prevent this outcome by managing the pressure consistently across the interior. They absorb some of the stress, redirect it, and keep liners from stretching disproportionately. This reduces the chance of catastrophic liner failure while also improving the longevity of the IBC itself.

Key Benefits of IBC Dunnage Boards

The value of dunnage boards extends well beyond reinforcement. Their use provides measurable improvements in container safety and efficiency.

Advantages Include

Working with Other Packaging Materials

While dunnage boards provide critical internal support, they are most effective when combined with other bulk liquid packaging components. IBC base pads protect liners from friction and wear at the bottom of the container, while IBC top lids and IBC container lids secure the liner from above and protect against contaminants. Open top liners can also be used in conjunction with dunnage boards for easier filling and inspection, especially for viscous or hard-to-handle liquids.

By serving as part of an integrated system, dunnage boards allow every IBC to function as a complete protective unit. They not only stabilize the product inside but also ensure that all other packaging components work together effectively. This combination creates a strong, dependable solution that transforms IBCs into safe and reliable shipping systems across industries ranging from food and beverage to chemicals, cosmetics, and automotive fluids.

How Do Base Pads Protect IBC Liners During Transport?

The base of an IBC is one of its most vulnerable points, and this is where many transport-related issues can arise.

Every time a container is moved with forklifts, placed on pallets, or positioned on warehouse floors, the bottom of the unit endures direct contact with hard surfaces. Without added protection, this constant exposure can create friction, vibration, and impact that gradually wear down the protective container liner. Over time, these stresses may result in premature liner failure or leaks that compromise the shipment. IBC base pads are designed to address these risks by creating a cushioning barrier between the liner and the rigid IBC floor.

Why Base Pads Are Essential

Base pads serve as an insulating layer that reduces the friction generated by liquid movement inside the container. Liquids naturally shift as containers are transported, loaded, or stacked. Even small shifts create consistent rubbing against the bottom surface, which weakens liners over repeated cycles. Base pads absorb this friction, lessening its direct impact on the liner and keeping the protective barrier intact.

By adding this layer of cushioning, base pads also allow containers to withstand repeated use without losing reliability. This makes them particularly valuable in high-volume shipping operations where IBCs are handled frequently and exposed to long-distance transport conditions.

Benefits of IBC Base Pads

The addition of base pads provides several clear benefits that improve safety and efficiency during bulk liquid shipping.

Advantages Include

Safety During Handling and Stacking

Base pads also improve safety during everyday handling. When IBCs are stacked or lifted, the bottom of the container takes on a significant amount of pressure. A base pad stabilizes the bottom layer, helping the liquid remain evenly distributed inside the liner. This reduces the risk of imbalance, which can otherwise lead to spills or accidents in warehouses and transport vehicles. The stability provided by base pads helps protect both the product and the workers handling the containers.

Integration with Other Packaging Components

Base pads achieve their best results when paired with other bulk liquid packaging components. IBC dunnage boards provide internal reinforcement by distributing liquid weight evenly, while protective container liners maintain hygiene and product integrity. At the top of the container, IBC top lids and IBC container lids seal the system, keeping contaminants out and ensuring the liner stays properly aligned. When combined with these elements, base pads complete the protective system by addressing bottom-up stress, creating a balanced and reinforced container capable of handling the rigors of bulk liquid transport.

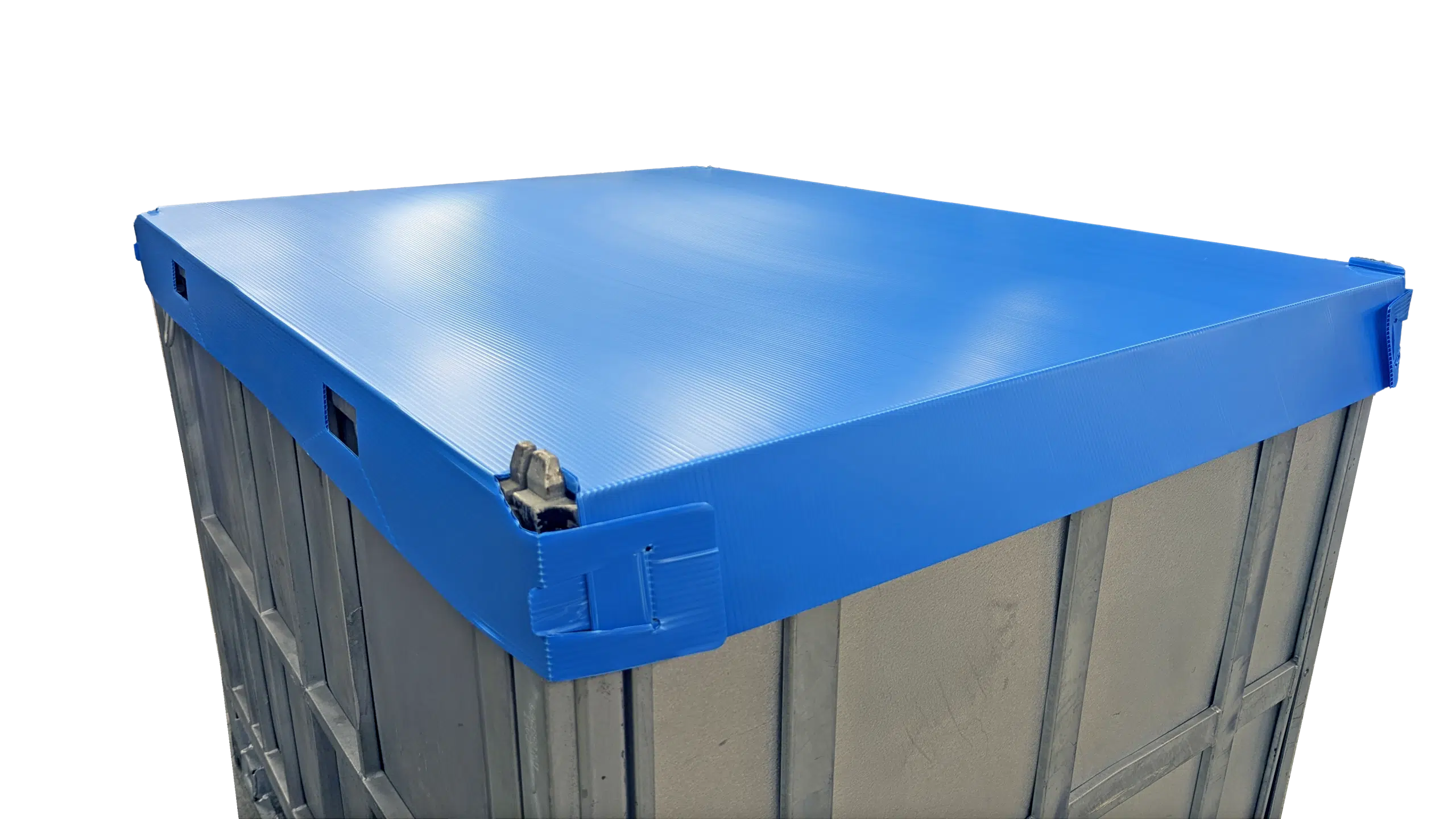

Why Are Top Lids Important For Bulk Liquid Packaging?

Sealing the container is just as important as reinforcing it. IBC top lids and IBC container lids serve as the final line of defense, preventing contaminants from entering and ensuring that the protective container liner remains secure.

While liners, dunnage boards, and base pads provide critical internal reinforcement, lids complete the system by protecting the container from external risks and keeping the product safe throughout transport and storage.

The Importance of Sealing

During storage and transit, bulk liquids are vulnerable to contamination from airborne particles, dust, dirt, and moisture. Even small amounts of foreign material can affect taste, purity, or chemical stability. In food and beverage industries, this could mean an unusable batch. In cosmetics or pharmaceuticals, contamination may lead to strict regulatory concerns. For industrial chemicals, impurities can impact performance or create safety risks.

IBC top lids provide a tight seal at the opening, keeping the container closed off from outside elements. By acting as a shield against environmental exposure, lids help maintain the integrity of the product from filling to final delivery.

How Top Lids Support Liners

In addition to blocking contaminants, lids play a crucial role in supporting the liner itself.

A protective container liner must stay in the proper position to perform effectively. If it shifts or folds during filling, transport, or dispensing, this can create creases that trap product, slow down flow, or even form weak points vulnerable to tearing.

By holding the liner securely in place, IBC top lids ensure proper alignment. This keeps the product moving smoothly during filling and dispensing while minimizing stress on the liner walls. The result is a more reliable packaging system that protects both the container and the liquid inside.

Benefits of IBC Top Lids and Container Lids

The addition of lids provides several advantages that directly improve safety, efficiency, and product protection:

Protect products from dust, debris, and airborne contaminants

Keep liners securely positioned inside the container for consistent performance

Reduce the risk of spills or leaks during shipping and handling

Preserve product quality during long storage or extended transit times

Improve handling efficiency by maintaining a closed, stable system

Industries That Depend on Top Lids

Top lids are especially critical in industries where purity, safety, and quality control are essential.

Food and beverage: Lids prevent outside contamination that could compromise taste, freshness, or compliance with health standards.

Pharmaceuticals and cosmetics: These industries require strict adherence to cleanliness, and lids create a controlled environment that protects delicate formulations.

Chemical transport: Lids help keep hazardous or reactive liquids contained and stable during shipping, reducing risks to workers and surrounding cargo.

By creating a secure seal, IBC top lids make containers suitable for use in highly regulated markets and give businesses confidence that their products will arrive uncontaminated and intact.

The Complete System of Bulk Liquid Packaging Components

Dunnage boards, base pads, and top lids each serve unique purposes, but their true value is realized when they work together as part of a complete protective system.

Along with open top liners, polypropylene container liner solutions, and other IBC protective packaging supplies, these components ensure that every angle of the container is reinforced.

How Components Work Together

Dunnage boards handle weight distribution inside the container.

Base pads protect the liner from bottom wear and abrasion.

Top lids seal the container, keeping contaminants out.

Open top liners provide flexibility for filling and inspection.

Polypropylene container liner options create the sterile barrier needed for food, chemical, and cosmetic applications.

This integrated system makes IBCs capable of handling demanding shipping conditions while maintaining safety, hygiene, and efficiency.

Sustainability Benefits of Using Protective Components

By reinforcing containers and extending liner life, dunnage boards, base pads, and lids also support sustainability. They reduce product waste, minimize the need for frequent liner replacement, and make container reuse easier by preserving IBC integrity. This reduces resource use, supports greener operations, and helps businesses align with environmental goals while improving cost efficiency. In addition, these bulk liquid packaging components cut down on the amount of water, energy, and chemicals required for cleaning, since liners remain protected and last longer. Over time, this contributes to a lower environmental footprint while ensuring companies meet both operational and sustainability targets.

Comprehensive Guide To IBC Packaging Materials And Components

Choosing the right combination of packaging components depends on the type of liquid being shipped, the conditions of transport, and industry-specific requirements. For a detailed breakdown of options, businesses can review the Comprehensive Guide To IBC Packaging Materials And Components. This resource provides valuable insight into liners, dunnage boards, base pads, lids, and other protective supplies to help companies select the best system for their needs.

Why Work With Innovative Liner Solutions

Innovative Liner Solutions provides a full range of IBC packaging materials, including dunnage boards, base pads, top lids, container lids, open top liners, and polypropylene container liner options. Their expertise ensures that every solution is tailored to meet the unique needs of different industries, from food and beverage to chemicals and cosmetics. By offering high-quality protective components, they help businesses maintain safety, efficiency, and sustainability in bulk liquid shipping.

Conclusion

Dunnage boards, base pads, and top lids may seem like small additions to an IBC system, but they play a critical role in protecting products and containers during storage and transport. When combined with liners and other bulk liquid packaging components, they create a comprehensive system that safeguards product quality, reinforces container durability, and improves logistics efficiency across industries.

Strengthen your IBC performance from every angle.

Innovative Liner Solutions offers high-quality dunnage boards, base pads, and top lids designed to protect liners, stabilize loads, and extend the life of your bulk liquid containers. Call 815-963-9525 today or contact Innovative Liner to speak with our team about finding the perfect solution for your operation.