How Protective Container Liners Improve Bulk Liquid Shipping

Bulk liquid packaging requires solutions that not only protect products but also streamline handling and transport. Intermediate Bulk Containers (IBCs) have become a standard across industries because of their efficiency, durability, and reusability. However, the performance of an IBC is largely determined by the packaging materials and components that support it. Among these, open top liners and polypropylene liners are two of the most versatile options available. Understanding when and how to use them is essential for businesses looking to improve safety, efficiency, and product protection.

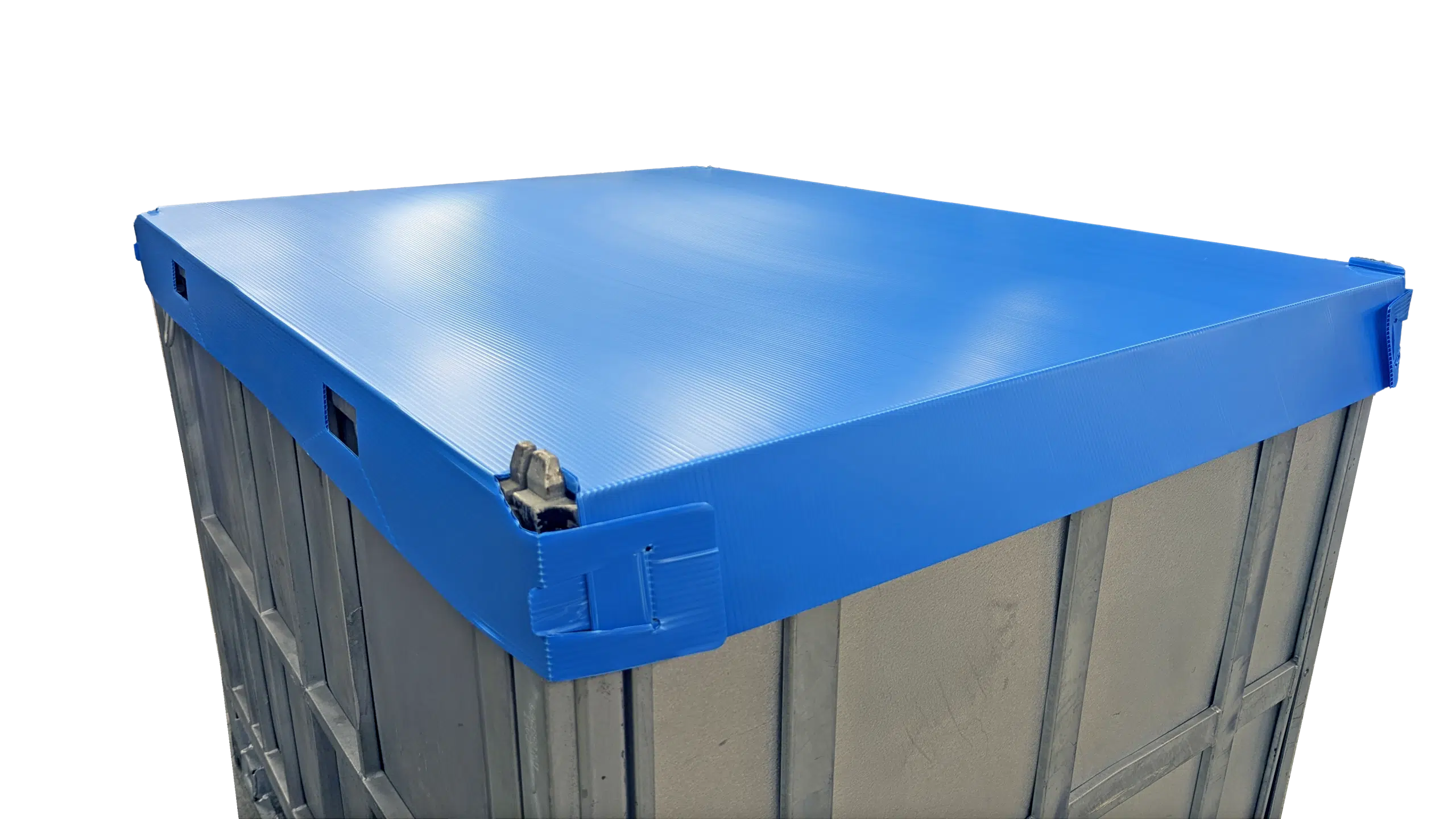

This page explores what polypropylene liners are, when open top liners are the better choice compared to standard liners, and how polypropylene liners compare to other IBC liner materials. Along the way, we will also highlight the importance of supporting IBC packaging materials such as IBC dunnage boards, IBC base pads, IBC top lids, and IBC container lids.

What is Polypropylene Liner?

Properties of Polypropylene Liners

Polypropylene is widely valued because of the specific properties that make it adaptable across industries. Its advantages go beyond simple durability, offering benefits that meet the needs of food, chemical, cosmetic, and automotive markets.

Key Properties Include:

Resistance to chemicals: Polypropylene stands up to acids, bases, and solvents, making it a reliable choice for transporting aggressive or corrosive liquids.

Lightweight and flexible design: Easy to fold, store, and install, the liners save time during setup while ensuring consistent performance.

Non-reactive and hygienic: The material does not alter or interact with liquids, an essential factor for food-grade, beverage, cosmetic, and pharmaceutical products.

Temperature tolerance: Polypropylene maintains performance in varying climates and can withstand temperature fluctuations without degrading or breaking down.

Strength and durability: The film resists punctures and tears, which provides extra security during filling, handling, and transport.

Why Businesses Use Polypropylene Liners

A polypropylene container liner is among the most versatile bulk liquid packaging components available. Its performance characteristics make it suitable for a wide range of industries.

Industries:

Food and beverage: Oils, syrups, juices, and other consumables remain uncontaminated and fresh.

Chemicals: Resistance to aggressive liquids ensures safe transport without container damage.

Cosmetics and pharmaceuticals: Hygienic surfaces keep sensitive products clean and compliant with industry standards.

Automotive: Products such as lubricants, coolants, and antifreeze are protected during shipping and storage.

Operational benefits for businesses:

Reduced downtime: By using liners, companies can switch quickly between products without dedicating time to intensive container cleaning.

Lower resource use: Liners reduce the amount of water, energy, and cleaning chemicals required.

Sustainability support: By conserving resources and extending IBC life, liners align operations with environmental and cost-saving goals.

Each component plays a specific role in reinforcing the system and preventing liner stress or container damage.

IBC dunnage boards: Distribute liquid weight evenly, reducing internal stress points and minimizing the risk of liner stretching or tearing.

IBC base pads: Cushion the bottom of the container, preventing friction and wear that could damage the liner during handling and transport.

IBC top lids and IBC container lids: Seal the container from above, protecting against airborne contaminants such as dust, dirt, or moisture, while securing the liner in place.

Open top liners: Can be used alongside polypropylene liners when wide access is required for filling or inspection, especially with viscous liquids.

When combined, these bulk liquid packaging components form a complete protective system. The liner provides the sterile barrier, the dunnage boards and base pads reinforce the structure, and the lids keep the system sealed from external risks. By working together, these materials maximize safety, durability, and efficiency, ensuring that IBCs deliver reliable performance across industries and applications.

Role with Other IBC Packaging Materials

Polypropylene liners are most effective when paired with complementary IBC protective packaging supplies.

When Should You Use Open Top Liners Instead Of Standard Liners?

Open top liners are another essential solution within IBC packaging. Unlike standard liners, which typically feature smaller fill or discharge openings, open top liners provide a wide access point at the top of the container.

This design makes them easier to fill, inspect, and remove, offering unique advantages for operations that require greater flexibility. While standard liners are well suited for many general applications, there are specific scenarios where open top liners are the better choice for safety, efficiency, and product integrity.

Advantages of Open Top Liners

Open top liners offer multiple operational benefits that address the challenges of handling bulk liquids:

Simplified Installation

Efficient Filling

Flexibility for Equipment

Easy Removal and Replacement

Improved Inspection

Situations Where Open Top Liners Are Ideal

Standard liners may suffice for free-flowing liquids or applications where changeovers are rare, but open top liners excel in situations where accessibility and flexibility are critical.

Best uses for open top liners include:

Handling viscous liquids: Liquids that do not flow easily benefit from the wide opening, which simplifies filling and reduces stress on pumping systems.

Frequent product changeovers: Industries with diverse product lines can quickly replace open top liners, making operations more agile.

Quality-driven environments: Businesses that must verify cleanliness and liner positioning, such as food, beverage, or cosmetic manufacturers, benefit from the visibility open tops provide.

Time-sensitive operations: Open top liners minimize downtime by streamlining both the filling and discharge process, improving overall efficiency.

Supporting Open Top Liners with Other Components

Like polypropylene liners, open top liners achieve the best results when integrated into a full system of bulk liquid packaging components. Each part plays a role in protecting both the liner and the product inside.

IBC base pads: Provide cushioning at the bottom of the container to protect liners from friction and wear during transport or handling.

IBC dunnage boards: Distribute internal liquid pressure evenly, preventing stress points that could damage liners.

IBC container lids and IBC top lids: Seal the system once the liner is in place, protecting against airborne contaminants while holding the liner securely.

By using open top liners alongside these IBC protective packaging supplies, businesses create a reinforced packaging solution capable of handling demanding shipping conditions. This integration ensures that liners remain intact, products stay uncontaminated, and operations achieve maximum reliability across industries.

How Do Polypropylene Liners Compare To Other IBC Liners?

Polypropylene liners are not the only liner option available, but they stand out for their versatility and performance.

Other liner types include polyethylene liners and multi-layer liners, each designed with unique benefits. However, polypropylene offers an ideal balance of cost-effectiveness, durability, and chemical resistance, making it one of the most widely used protective container liner solutions.

Comparison with Polyethylene Liners

Polyethylene liners are popular because of their affordability and ease of use. They work well for basic applications involving non-aggressive liquids, and many businesses rely on them for general shipping and storage needs. However, polyethylene does not provide the same level of resistance to solvents, acids, and bases as polypropylene. For industries that handle chemicals or liquids requiring strong protective properties, a polypropylene container liner is far more reliable. Polypropylene also tends to perform better under temperature fluctuations, reducing the risk of degradation during long-distance transport or varied storage conditions.

Comparison with Multi-Layer Liners

Multi-layer liners are engineered using several film layers to create specialized barriers. They can be highly effective for niche applications, such as protecting against oxygen intrusion, moisture transfer, or highly aggressive chemicals. While these liners deliver strong protection, they can also be more expensive, complex to manufacture, and sometimes overbuilt for general liquid shipping. In contrast, polypropylene liners provide a flexible, cost-effective solution that covers a wide range of applications without requiring specialized handling or higher upfront costs.

Why Polypropylene Stands Out

Polypropylene liners combine strength, hygiene, and adaptability in one material. They are strong enough to transport industrial chemicals, safe enough for food and beverage products, and flexible enough for cosmetics and pharmaceuticals. Their ability to cut down on cleaning requirements also makes them more sustainable and cost-effective over time, reducing both operational downtime and environmental impact.

Integration with Protective Supplies

Polypropylene liners are most effective when used as part of a complete IBC packaging system. Paired with IBC dunnage boards for weight distribution, IBC base pads for cushioning, and IBC top lids or IBC container lids for sealing, these liners become part of a reinforced structure that keeps liquids safe during transport and storage. This system of bulk liquid packaging components ensures durability, efficiency, and maximum product protection across industries.

Comprehensive Protection Through Bulk Liquid Packaging Components

Choosing between open top liners and polypropylene liners often depends on the specific requirements of the product being shipped. However, both options are part of a broader system of IBC packaging materials that must work together for maximum protection.

How the System Works

Protective container liner options like polypropylene or open top liners create the barrier between the product and the container walls.

IBC dunnage boards distribute liquid weight evenly, reducing stress points on liners.

IBC base pads cushion the bottom, preventing friction and wear during handling.

IBC top lids and IBC container lids seal the system, keeping contaminants out and liners properly aligned.

By using these bulk liquid packaging components together, businesses can achieve the highest level of product safety and transport reliability.

Sustainability and Efficiency Benefits

Comprehensive Guide To IBC Packaging Materials And Components

For businesses looking to learn more about selecting the right liners and protective supplies, the Comprehensive Guide To IBC Packaging Materials And Components provides an in-depth overview of the available options. This resource highlights how liners, dunnage boards, base pads, top lids, and container lids work together as part of a complete system.

Why Work With Innovative Liner Solutions

Innovative Liner Solutions provides both open top liners and polypropylene container liner options, along with a full range of IBC protective packaging supplies. Their expertise ensures that businesses across industries receive packaging systems tailored to their specific needs. By offering durable, high-quality components, Innovative Liner Solutions helps companies maintain product integrity, reduce risks, and improve efficiency throughout bulk liquid shipping.

Conclusion

Choosing the right liner is an important decision for businesses that rely on bulk liquid packaging. Polypropylene liners offer unmatched versatility, durability, and chemical resistance, while open top liners provide accessibility and ease of use for specific applications. Both play essential roles in protecting products, ensuring cleanliness, and supporting sustainable operations.

Not sure which liner fits your operation best?

Innovative Liner Solutions can help you choose between open top liners and polypropylene liners, ensuring you get the right balance of flexibility, strength, and protection for your bulk liquid applications. Call 815-963-9525 today or contact Innovative Liner to speak with our team about finding the perfect solution for your operation.