Intermediate Bulk Containers (IBCs) are designed to move large volumes of liquid safely and efficiently. While the container itself is durable, its effectiveness depends on the supporting components that reinforce its structure. One of the most important but sometimes overlooked elements is the IBC dunnage board. These boards play a critical role in protecting the container, its liner, and ultimately the product being transported. Understanding what dunnage boards do in an IBC container helps businesses see how small details make a big difference in bulk liquid packaging systems.

Understanding IBC Dunnage Boards

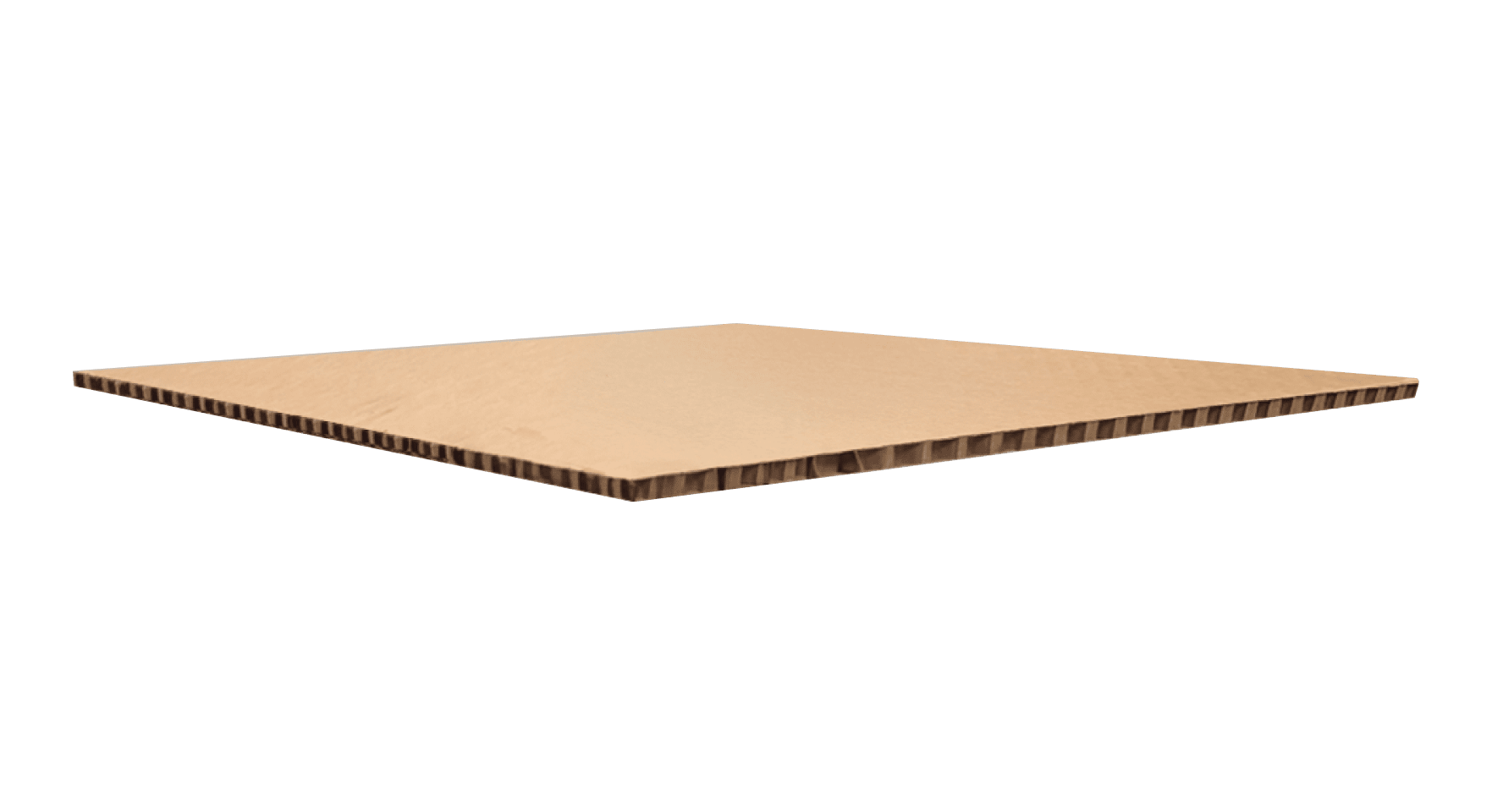

An IBC dunnage board is a structural support panel placed inside the container to distribute weight evenly and prevent excess stress on any single point of the liner or container walls. Because bulk liquids exert pressure in all directions, a container without proper support can suffer damage over time, which increases the risk of leaks, contamination, or product loss. Dunnage boards are designed to absorb this pressure, stabilizing the IBC and prolonging its usable life.

These boards are just one part of a complete family of IBC packaging materials. Alongside liners, lids, and pads, dunnage boards contribute to creating a secure and contamination-free environment for shipping sensitive liquids.

Why Dunnage Boards Are Essential for Bulk Liquids

When an IBC is filled with hundreds of gallons of liquid, the weight pressing against the liner is substantial. Without reinforcement, liners could shift, stretch, or wear down unevenly. Dunnage boards prevent this by spreading the load across a broader area, which protects both the liner and the container.

This protection is especially important when using a protective container liner such as a polypropylene container liner. By preventing stress points and sharp bends, dunnage boards help maintain the integrity of the liner and reduce the chance of punctures or leaks during transportation.

The Role of Dunnage Boards, Base Pads, And Top Lids In IBCs

Dunnage boards work most effectively as part of a complete protective system. Together with base pads and top lids, they ensure that the container remains stable and secure from all sides. Base pads cushion the bottom of the IBC, reducing wear during movement and handling. Top lids or IBC container lids protect the opening, keeping contaminants and debris from entering the container. By combining these elements, businesses gain a fully reinforced system. To explore these elements in more detail, review this resource on The Role Of Dunnage Boards, Base Pads, And Top Lids In IBCs.

How Dunnage Boards Protect Liners

Protective liners are designed to prevent contamination by creating a barrier between the liquid and the container wall. However, liners are flexible, and when exposed to concentrated pressure, they can wear down more quickly. Dunnage boards prevent this by ensuring that pressure from the liquid is distributed evenly, reducing the chance of weak spots. This not only extends the life of the liner but also minimizes the risk of leaks during long-distance shipping.

For applications using open top liners, dunnage boards are particularly valuable because they hold the liner in place more securely. This prevents shifting or folding that could otherwise cause product handling issues.

Supporting Bulk Liquid Packaging Components

In addition to dunnage boards, there are several bulk liquid packaging components that work together to make IBCs reliable. These include:

-

IBC base pads that protect the bottom layer and improve container stability.

-

IBC top lids and IBC container lids that provide a sealed closure to maintain a clean environment.

-

Open top liners that make installation and replacement easier, especially for thicker or high-viscosity liquids.

Each of these components complements the function of the dunnage board, ensuring that the IBC is reinforced from top to bottom.

Benefits Across Industries

Industries ranging from food and beverage to chemicals and cosmetics rely on dunnage boards for safe shipping. In food applications, they ensure that edible liquids like juices and oils remain uncontaminated by protecting the liner. In chemical applications, they help contain corrosive or hazardous liquids by reducing strain on the liner and container. Cosmetic producers also use them to protect delicate products such as creams or gels during long-haul transport.

The consistent benefit across these industries is that dunnage boards reduce risk, extend container life, and improve overall safety during shipping and storage.

Sustainability Advantages

Using dunnage boards and related components is also part of a sustainable packaging strategy. By extending the life of liners and containers, businesses reduce the frequency of replacements, which in turn lowers waste. Combined with protective liners, dunnage boards help reduce the need for harsh cleaning processes, conserving water, energy, and cleaning chemicals. This makes them a practical choice for companies that want to align their operations with environmental goals.

Choosing the Right Packaging System

Selecting the right IBC protective packaging supplies requires understanding the properties of the liquid, the shipping conditions, and the desired level of protection. Dunnage boards come in different designs and can be paired with base pads, top lids, and liners to create a customized solution. For businesses that need detailed guidance, the Comprehensive Guide To IBC Packaging Materials And Components is a valuable resource for exploring the full range of available options.

Why Work With Innovative Liner Solutions

Innovative Liner Solutions provides a complete range of IBC packaging materials, including dunnage boards, liners, base pads, top lids, and container lids. Their expertise ensures that businesses can build protective systems tailored to their unique products and industries. By partnering with a provider that understands both the technical and operational demands of bulk liquid shipping, companies gain peace of mind knowing their containers are reinforced against contamination and damage.

Conclusion

Dunnage boards are a critical component of any IBC container system. They stabilize loads, protect liners, and extend the life of both the liner and the container itself. When combined with base pads, top lids, and other protective components, they create a reliable and efficient system for transporting bulk liquids across industries. Businesses looking to improve product safety, reduce waste, and extend the life of their packaging should consider how dunnage boards fit into their overall strategy.

For expert advice on IBC dunnage boards and protective packaging systems, contact Innovative Liner Solutions today at (815) 963-9525.