IBC liquid refers to any liquid stored and transported in an Intermediate Bulk Container (IBC). IBCs are versatile, large-capacity containers widely used in industries such as food and beverage, pharmaceuticals, chemicals, and industrial manufacturing. When paired with appropriate IBC liners or liquid tote liners, these containers ensure safe handling, maintain product integrity, and optimize efficiency across the supply chain.

Whether you’re shipping juices, oils, adhesives, or industrial fluids, understanding what qualifies as IBC liquid and how it is managed is key to successful bulk liquid operations.

Understanding IBC Liquids

An IBC liquid can include virtually any fluid compatible with bulk liquid packaging, from consumable products to chemicals. The defining characteristic is that the liquid is stored within an IBC, often ranging from 275 to 330 gallons, allowing large volumes to be handled in a single container.

IBCs typically consist of a rigid plastic inner tank, usually made of high-density polyethylene (HDPE), supported by a metal or plastic outer cage. In some cases, stainless steel IBCs are used for highly corrosive or regulated liquids. The inner liner, such as an IBC liner bag or liquid bulk container liner, acts as a protective barrier between the liquid and the container, ensuring safety and hygiene.

Types of IBC Liquids

IBC liquids vary based on viscosity, chemical composition, and regulatory requirements. Common categories include:

- Food and Beverage Liquids: Juices, syrups, oils, sauces, and dairy concentrates. Using liquid tote liners ensures hygiene and prevents contamination.

- Pharmaceutical Liquids: Sterile solutions, active ingredients, and medicinal liquids require barrier liners to protect from moisture and oxygen exposure.

- Industrial Liquids: Paints, resins, adhesives, and lubricants benefit from industrial IBC liners that offer durability and chemical resistance.

- Chemicals: Detergents, acids, and solvents often need anti-static or high-resistance bulk liners for safe transport and storage.

By matching the right liner with the type of IBC liquid, businesses can ensure safe handling and maximize operational efficiency.

The Role of IBC Liners

Intermediate bulk container liners are essential for managing IBC liquids. They act as a flexible barrier between the liquid and the container, preventing contamination and product loss. Benefits include:

- Maintaining Product Integrity: Liners protect liquids from contamination and exposure.

- Minimizing Residue: Efficient filling and dispensing reduce waste.

- Reducing Cleaning Downtime: Liners eliminate the need for extensive washing between uses.

- Versatility: Liners allow the same IBC container to handle multiple types of liquids by changing the liner.

Popular liner types include pillow-style liners for food and beverage applications, form-fit liners for viscous products, and barrier liners for sensitive liquids. For detailed guidance on liner selection and best practices, consult The Ultimate Guide To IBC Liners And Bulk Liquid Packaging.

Applications Across Industries

IBC liquids are found across multiple industries, each with specific liner and container requirements:

- Food and Beverage: Juices, edible oils, sauces, and syrups require hygienic liquid tote liners to maintain freshness and prevent contamination.

- Pharmaceuticals: Active ingredients and sterile solutions need barrier IBC liners to comply with regulatory standards.

- Chemicals and Industrial Fluids: Flammable, corrosive, or sensitive liquids benefit from industrial IBC liners and anti-static liners for safe handling.

- Cosmetics and Personal Care: Lotions, creams, gels, and oils are efficiently handled with pillow-style or form-fit liners to reduce residue.

Using the appropriate IBC tote liners for sale ensures that liquid products reach their destination safely while minimizing operational challenges.

Filling and Dispensing IBC Liquids

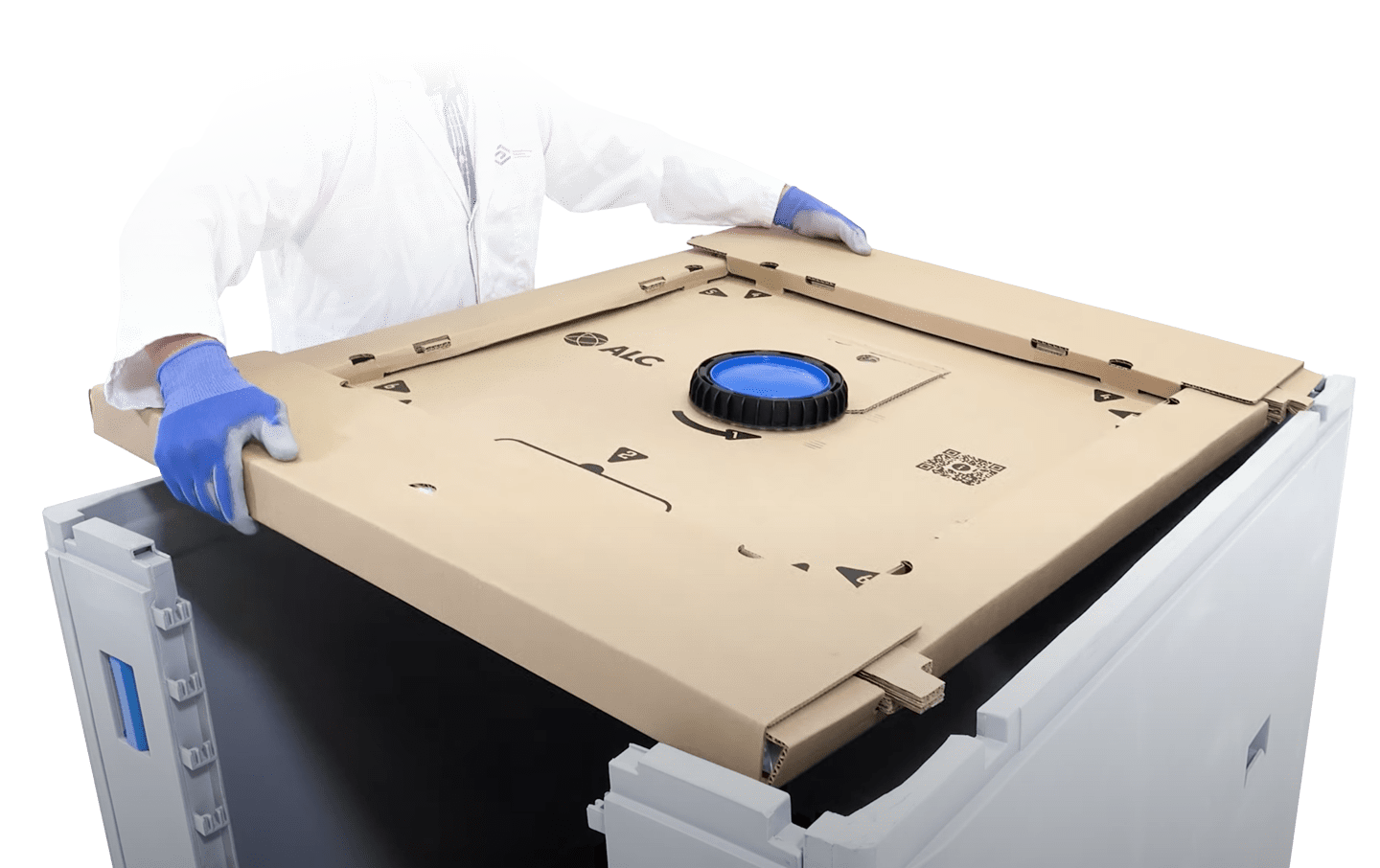

The volume and nature of the IBC liquid impact how the container is filled and emptied. IBC liner bags are available for both top-fill and bottom-drain applications.

- Top-fill liners allow liquids to be poured gently into the container, suitable for foamy or sensitive liquids.

- Bottom-drain liners enable near-complete evacuation, ideal for viscous or valuable liquids, reducing waste and speeding up discharge.

Selecting the right liner and dispensing method ensures that IBC liquids are handled efficiently and safely.

Advantages of Proper IBC Liquid Management

Properly managing IBC liquids with the correct bulk liquid packaging solutions and liners offers several benefits:

- Safety: Reduces risk of leaks, spills, or contamination.

- Efficiency: Faster filling and dispensing processes.

- Cost Savings: Reduces cleaning, labor, and product loss.

- Versatility: One IBC container can handle multiple liquid types by changing liners.

By integrating high-quality IBC tank liners or bulk liners, businesses can streamline liquid handling and optimize their supply chain operations.

IBC liquids represent a wide range of products transported and stored in intermediate bulk containers. Pairing these containers with the right IBC liners, liquid tote liners, and industrial IBC liners ensures safety, hygiene, and operational efficiency.

Whether you are managing food, pharmaceuticals, chemicals, or industrial liquids, investing in the correct liner and container combination maximizes performance and minimizes risk.

Want to optimize handling and storage of IBC liquids?

Call 815-963-9525 today to speak with Innovative Liner Solutions. Our team will help you select the ideal IBC liners, bulk liners, and liquid tote liners for your operation.