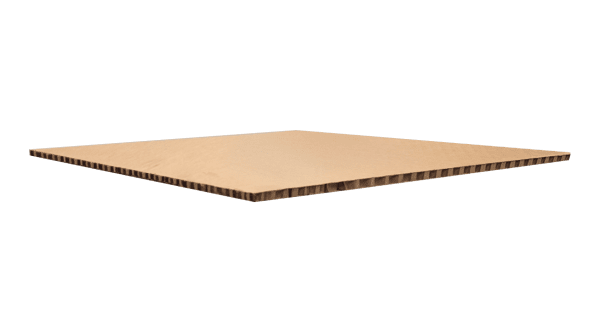

Dunnage Boards

Packaging MaterialsDunnage can be any material that will compress to fill the space on the top of the filled bag and prevent the wave action of the liquid during transportation. There are many types of dunnage including foam, paper and plastic. ILS typically uses corrugated paper dunnage in thickness of 1” or greater.

Need Help Finding the Right Products for Your Needs?

Optimize your IBC liner setup today at 815-963-9525 or visit our online inquiry page to discuss your specific needs.

Description

Flex cracking is caused by the movement of the liquid inside the bag, and it is most likely to happen where the film is in proximity to the upper part of the liquid. In order to prevent flex cracking we suggest to use dunnage to fill the space between the top of the filled bag and the lid of the container. Dunnage can be any material that will compress to fill the space on the top of the filled bag and prevent the wave action of the liquid during transportation.

There are many types of dunnage including foam, paper and plastic. ILS typically uses corrugated paper dunnage in thickness of 1” or greater.