IBC Packaging Materials

High-Performance IBC Packaging Materials for Maximum Product Protection

We understand the critical role packaging materials play in maintaining product integrity, reducing contamination, and supporting operational efficiency. Our full line of IBC packaging components is engineered to complement our IBC liners and accessories—creating a complete, dependable solution for bulk liquid transport. Our innovative packaging materials ensure that your bulk liquid containers deliver unmatched safety and performance from start to finish.

Types of IBC Packaging Materials

Innovative Liner Solutions offers a diverse range of packaging materials tailored to meet unique needs.

Protective Container Liner

The PCL is a woven polypropylene layer designed to create a protective barrier between the bin and the liquid liner. This helps protect the liquid liner from rubbing against the bin and causing damage during transport.

Dunnage Boards

Flex cracking is caused by the movement of the liquid inside the bag, and it is most likely to happen where the film is in proximity to the upper part of the liquid. In order to prevent flex cracking we suggest to use dunnage to fill the space between the top of the filled bag and the lid of the container.

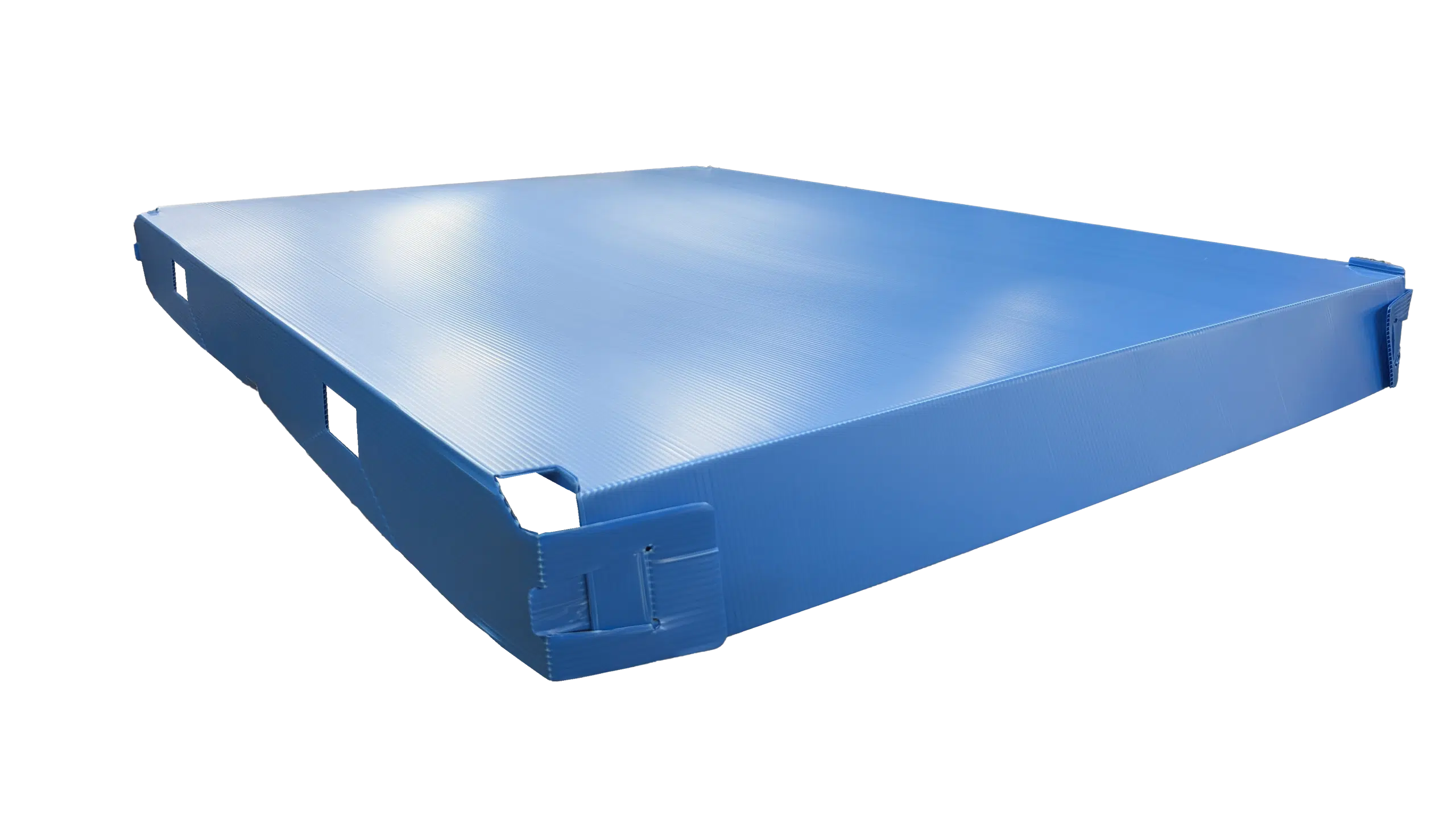

Top Lid

In some instances, IBC’s do not come with a top closure. ILS provides a solution to get your bin ready to ship. We have standard corrugated lids and also plastic lids for outdoor all weather use.

Open Top Liners

Also known as open-ended or open-top liner bags, they are designed to protect the inside of shipping containers from product contamination, especially when transporting dry bulk materials like powders or granules.

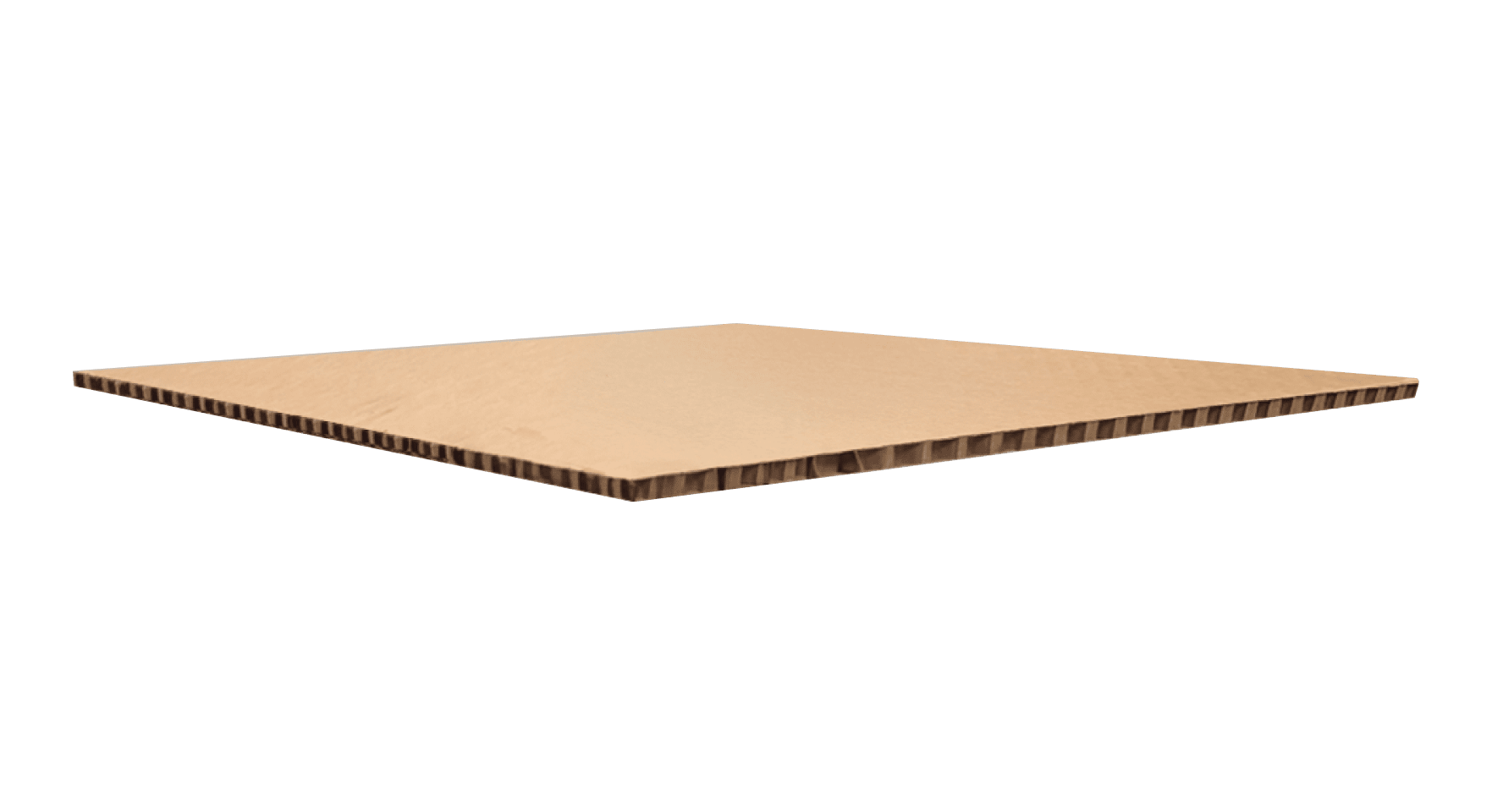

Base Pads

IBC’s can have potentially sharp edges from continued use and can also be designed with hinges or problem areas that can result in damage to the Liquid Liner during transport. ILS suggests using a corrugated Base Pad that blankets the bottom surface and several inches up the side of the IBC. This provides a smooth surface and extra protection against any issues with the IBC when shipping long distances.

Find the Right IBC Solutions for Your Business

Optimize your liquid handling operations with our high-quality IBC liners, containers, valves, connectors, discharge tubes, and more. No matter your industry—food processing, chemicals, pharmaceuticals, or manufacturing—we have the solutions you need. Contact us today for pricing and expert guidance!